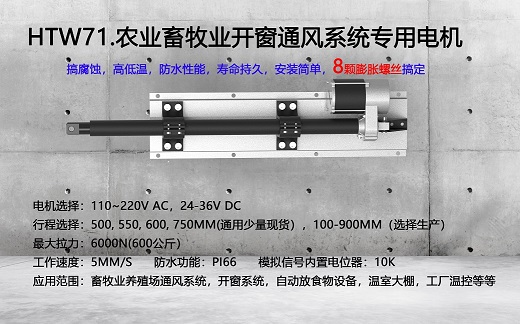

Learn how to use 12 V and 24 V DC motors to convert electrical energy into mechanical motion in modern industrial linear actuators and familiarize yourself with the most common motor components such as brushes, gears and permanent magnets.

A direct current (DC) motor is a rotating machine that converts electrical energy into mechanical energy. This function is based on the principle of induction – the electromagnetic force is generated by the input current, which in turn produces a rotary motion.

The performance of a DC motor is the relationship between input power and output power, measured in watts. Many motor components affect (reduce the impact) motor performance and generate heat. This also applies to very high or very low ambient temperatures and is often part of the working environment of industrial linear actuators.

But there are usually ways to ensure that the DC gear motor is highly efficient.

In order to achieve optimal motor performance, a stable power supply is required, and the cabling and input voltage must be guaranteed to be correct, as both are equally important for optimum performance. To learn more about the factors that affect motor performance, check out the video above.

For any questions regarding DC DC motors for industrial electric linear actuators, please feel free to contact GeMinG's staff.

Product

Product Industrial Use

Industrial Use Furniture & medical Use

Furniture & medical Use PV Drive

PV Drive Collaborative Robots

Collaborative Robots About us

About us Culture

Culture Milestone

Milestone Responsibility

Responsibility Contact Us

Contact Us News and Events

News and Events Global agents

Global agents Certificate

Certificate GeMinG

GeMinG English

English