In modern industrial manufacturing and economic development, a large part has a certain relationship with the gear motor. In the geared motor, the application of the planetary reducer has an irreplaceable application. The chrome drive simply introduces the advantages of the planetary reducer. Uses; planetary reducer advantages: high precision, high rigidity, high load, rate, high speed ratio, high life, low inertia, low vibration, low noise, low temperature rise, beautiful appearance, light structure, easy installation, positioning, etc. Features, suitable for AC servo motor, DC servo motor, stepper motor, hydraulic motor speed increase and reduce drive. The transmission efficiency of planetary reducers is generally above 90%, and the application is very extensive...

The main purpose

Motor unit data sheet

|

motor model model |

Rated voltage V DC |

No-load speed R/MIN |

No-load current MA |

Rated speed R/MIN |

Rated torque G.CN |

Output Power W |

Rated current A |

Stalling torque G.CN |

Stall current A |

|

395-12K |

12 |

8000 |

200 |

6600 |

110 |

8.5 |

1.3 |

660 |

6.5 |

|

395-24K |

24 |

8000 |

100 |

6800 |

110 |

8.5 |

0.6 |

670 |

3.2 |

Planetary geared motor data sheet

| Model | Reduction ratio | 1:3.7 |

1:5.2 |

1:14 |

1:19 |

1:27 |

1:51 |

1:71 | 1:100 |

1:139 |

1:189 |

1:264 |

1:369 |

1:515 |

1:721 |

|

|

|

No-load speed |

Rpm |

2100 |

1500 |

560 |

410 |

280 |

150 |

105 |

78 |

55 |

41 |

30 |

21 |

15 |

10.5 |

|

Rated torque |

Kg.cm |

0.3 |

0.4 |

1.0 |

1.4 |

2.0 |

3.3 |

4.6 |

6.5 |

9.0 |

11 |

15 |

20 |

20 |

20 |

|

|

Rated speed |

Rpm |

1800 |

1300 |

500 |

360 |

250 |

135 |

95 |

69 |

50 |

37 |

26 |

18.6 |

13.8 |

10 |

|

|

Instant torque |

Kg.cm |

0.6 |

0.8 |

2.0 |

2.8 |

4.0 |

6.0 |

9.0 |

12 |

18 |

22 |

30 |

40 |

40 |

40 |

|

|

|

No-load speed |

Rpm |

2100 |

1500 |

560 |

410 |

280 |

150 |

105 |

78 |

55 |

41 |

30 |

21 |

15 |

10.5 |

|

Rated torque |

Kg.cm |

0.3 |

0.4 |

1.0 |

1.4 |

2.0 |

3.3 |

4.6 |

6.5 |

9.0 |

11 |

15 |

20 |

20 |

20 |

|

|

Rated speed |

Rpm |

1800 |

1300 |

500 |

360 |

250 |

135 |

95 |

69 |

50 |

37 |

26 |

18.6 |

13.8 |

10 |

|

|

Instant torque |

Kg.cm |

0.6 |

0.8 |

2.0 |

2.8 |

4.0 |

6.0 |

9.0 |

12 |

18 |

22 |

30 |

40 |

40 |

40 |

|

|

L(MM) |

27.5 |

35.5 |

43.5 |

51.5 |

||||||||||||

|

Swing gap |

o |

0.7 |

0.8 |

1.0 |

1.0 |

|||||||||||

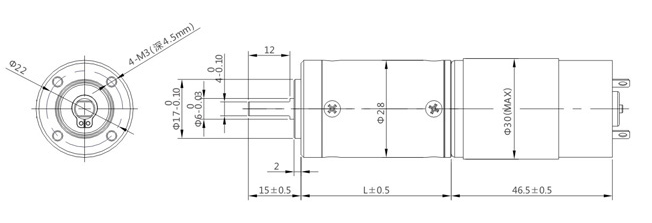

Drawings