On October 18, 2019, the 2019 World Smart Manufacturing Conference co-sponsored by the Ministry of Industry and Information Technology was grandly opened in Nanjing. Nearly 2,000 representatives from institutions, universities and research institutes, well-known enterprises, exhibitors and media reporters in the field of intelligent manufacturing at home and abroad attended the opening ceremony.

The opening ceremony of the 2019 World Smart Manufacturing Conference

During the three-day World Intelligent Manufacturing Conference, the most noticeable was the opening ceremony yesterday morning and the summit forum in the afternoon. Officials from the Ministry of Industry and Information Technology, the Chinese Academy of Engineering, the Chinese Science and Technology Association, well-known foreign institutions and well-known enterprises, academicians and big coffees delivered wonderful speeches and shared some insights from the conference.

Xiaobian participated in the 4th World Intelligent Manufacturing Conference this year. Let me share with you the comments and opinions of yesterday's Great Coffee. I hope you understand the essence of this meeting.

First of all, at today's opening ceremony, as one of the organizers of the meeting, Governor Wu Zhenglong of Jiangsu Province attended the meeting and delivered an opening speech. Wu Zhenglong pointed out that the Internet, big data and modern information technology are constantly changing. As the main direction to promote industrial technological change and optimization and upgrading, intelligent manufacturing will surely usher in better development opportunities. Wu Zhenglong said that Jiangsu, as a large manufacturing province and a large manufacturing province, has a complete industrial chain and a complete industrial chain. In the critical period of industrial upgrading and high-quality development, the development of smart manufacturing opportunities is rare. For building advanced manufacturing systems and promoting high-quality development,

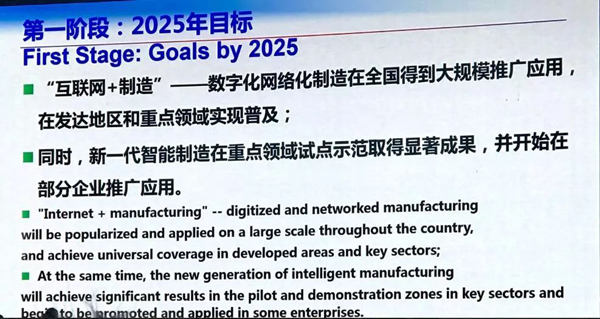

With the most significant significance, Jiangsu will build a 2025 Jiangsu sample made in China.

Xin Guobin, Deputy Minister of Industry and Information Technology Subsequently, Xin Guobin, Deputy Minister of Industry and Information Technology, said that since 2010, China ’s total manufacturing volume in the world has ranked first in the world for nine consecutive years. At present, China's intelligent manufacturing has entered the stage of deepening application and comprehensive promotion from the initial concept promotion and pilot demonstration. Man-machine war is no longer anecdotal. Today, the University of Newcastle has successfully printed 3D corneal and financial robots that can complete 360,000 hours of human work in seconds. Xin Guobin believes that the current new round of technological revolution is emerging, and intelligent manufacturing has become the main trend in the development of manufacturing. Xin Guobin introduced that the development of China's intelligent manufacturing is embodied in three aspects: first, to promote the application and promotion from a single enterprise pilot demonstration to the industry; second, the supply capacity from the local to the system is continuously improved, and a large number of System solutions.

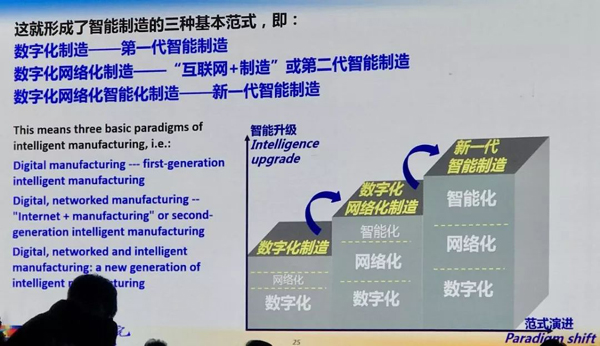

This field is iteratively upgraded. Third, the development model has evolved from elements to ecology, and has formed an intelligent manufacturing ecosystem including public services, policy guidance and personnel training. Xin Guobin said that practice has proved that the development of China's intelligent manufacturing has not only effectively promoted the improvement of manufacturing quality and efficiency, formed a model that can be replicated and promoted, but also continues to cultivate new growth points. Academician of Chinese Academy of Engineering believes that the next generation of artificial intelligence technology and advanced manufacturing technology will lead to the emergence of production lines, workshops and factories.

With revolutionary changes, enterprises will move towards a new generation of smart factories with self-learning, adaptive and self-control capabilities. The technological transformation and intelligent upgrade of the company's production capacity not only solve the problems of labor shortage and high labor costs in the front line, but also fundamentally improve the quality, efficiency and competitiveness of the manufacturing industry. The new generation of intelligent manufacturing, characterized by the intelligence of digital network text, will become an important focus for future transformation and upgrading of enterprises. It is expected that by 2035, China's various products and equipment will develop from the digital generation to the intelligent generation.

Chairman Reinhart Poprawe, Chairman and Chairman of the International Committee of Aachen University of Technology China Affairs Reinhart Poprawe What is the future development trend of smart manufacturing?

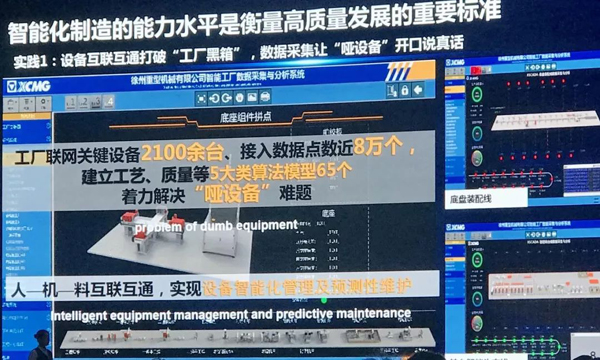

According to Reinhard Poprawi, chairman of the International Committee of the Aachen University of Technology in Germany, the goal of the future development of the human industry is personalized manufacturing. In order to make the industrial chain more simplified, as long as appropriate methods are adopted, products can be produced by simpler and smarter methods. He believes that the current data pool is too large. It is necessary to continuously simplify data, obtain data related to Industry 4.0, sort out new logic and processes of industrial data, and promote the intelligent and flexible development of modern manufacturing. As a leading company in the construction machinery industry, XCMG Group has become a representative of Shenxin's transformation. Wang Min, Chairman of Xugong Group and Secretary of the Party Committee, made a keynote speech on intelligent transformation and activation of new industrial energy. Wang Min said that XCMG has established an intelligent factory data collection and analysis system. There are more than 2,100 key devices connected to the factory, and it can access nearly 80,000 data points. The production process ranges from man-machine dialogue to machine dialogue.

By equipping the machine with an industrial mind, XCMG's production efficiency has been greatly improved, operating costs, product development cycles, and one-time inspection failure rates have also dropped significantly.

At the opening ceremony, there were leaders' speeches and expert keynote speeches in the morning. The World Intelligent Manufacturing Conference Summit Forum was held in the afternoon. The strategy of industrial intelligence transformation: roads can be copied, the supporting elements of industrial intelligence: technology can be realized and the mission of industrial intelligence is to explore Three themes of sustainable development. Shi An, President of Rockwell Automation Greater China President of Rockwell Automation Greater China

When discussing the industrial intelligent transformation strategy: a road that can be copied, Rock An Automation Greater China President Shi An believes that intelligent manufacturing cannot be used for intelligent manufacturing, and the development of intelligent manufacturing has emerged as the times require. Excessively heterogeneous intelligent manufacturing will lead to new overcapacity. He also analyzed the differences between Chinese and American manufacturing. He believes that the proportion of SMEs in China is very high, reaching over 95. Another point is that although there are 40 million non-manufacturing personnel in China's manufacturing industry, the number of people engaged in lean manufacturing is less than 25,000. Too small. So to change from China to Chinese smart manufacturing, we must first have the concept of lean manufacturing, otherwise smart manufacturing is also a waste.

Xiong Xiong, Senior Vice President of Strategy and Development of Schneider Electric China Co., Ltd. Yiong Yi, Senior Vice President of Strategy and Development of Schneider Electric China Co., Ltd. agreed. He also said that the real goal of developing intelligent manufacturing is to improve work efficiency while reducing costs, ensuring safety in the production process, and achieving green sustainable development.

Gu Jiandang, President of Fenghuang Electric China Gu Jiandang, President of Fenghuang Electric China, shared his ideas and practices to explore smart strategies and digital transformation in a dialogue. He believes that considering how technology can be transformed into the digital capabilities of an enterprise, only by using digitalization to improve internal efficiency and develop new business models can an enterprise upgrade become possible.

For the past five years, Phoenix has been thinking about what customers value in the digital age. Back to the original point is quality, cost and delivery. Over the past five years, Phoenix has been committed to building digital capabilities, breaking the company's internal boundaries and improving its overall competitiveness in these three areas. Mr. Gu Jiandang emphasized the need to reshape technology-centric digital capabilities, take customer value as the core business model, take human resources as the core of enterprise management, and consolidate the iron triangle to realize intelligent manufacturing.

Zhu Xingming, Chairman and President of Shenzhen Huichuan Technology Co., Ltd.

Intelligent manufacturing first is manufacturing, and manufacturing is divided into manufacturing and manufacturing methods. Intelligence is only a means to serve both. Zhu Xingming, chairman and president of Shenzhen Huichuan Technology Co., Ltd., explained his own understanding of intelligent manufacturing. He also emphasized that without a single point of automation, there is no intelligence.

In plain terms, the so-called single-point automation is the intelligent development of a group of machines instead of humans, and these machines must be supported by basic technology.

Zhu Jian, Founder of Hollow Technology Group In addition, Zhu Jian, Founder of Hollow Technology Group and founder of Ningbo Industrial Internet Research Institute, presided over the mission of industrial intelligence: discussion on the topic of sustainable development, and summarized the opinions of the guests participating in the discussion. The 2019 World Smart Manufacturing Conference ended today in Nanjing. According to statistics, more than 300 important guests from more than 20 countries and regions attended the conference, including: 20 Chinese and foreign academicians and experts in the field of intelligent manufacturing, including universities.

124 experts, 46 agent representatives and 168 industry leaders attracted nearly 2,000 companies to the exhibition.

Looking forward to next year's World Intelligent Manufacturing Conference

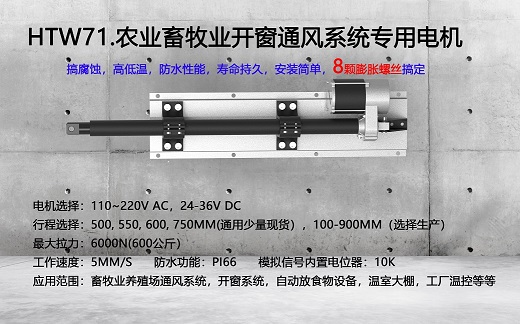

Lifting column, electric lifting column, medical lifting column, furniture lifting column, industrial lifting column, industrial lifting platform, office lifting platform

Product

Product Industrial Use

Industrial Use Furniture & medical Use

Furniture & medical Use PV Drive

PV Drive Collaborative Robots

Collaborative Robots Technical Support

Technical Support About us

About us Culture

Culture Milestone

Milestone Responsibility

Responsibility Contact Us

Contact Us News and Events

News and Events Global agents

Global agents Certificate

Certificate GeMinG

GeMinG English

English